Nitter

As one of professional manufacturer in China, Notin would like to provide you Rivets. And we will offer you the best after-sale service and timely delivery.

What is a rivet?

A rivet is a permanent mechanical fastener used to join two or more materials. Rivets work by inserting a metal pin into an aligned hole and deforming the end, creating a strong, secure, and durable connection. Unlike temporary fasteners like screws, rivets do not rely on threads, but instead form a permanent connection, making them ideal for applications requiring high strength, durability, and vibration resistance.

Classification of Rivets

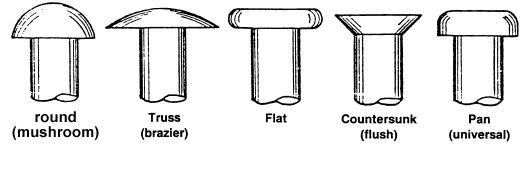

Rivets are typically categorized by head shape, degree of hollowness, or material.

Based on head shape, rivets can be classified as flat head rivets, round head rivets, countersunk head rivets, mushroom head rivets, universal head rivets, truss head rivets, etc.

Based on degree of hollowness, rivets can be classified as solid rivets, semi-tubular rivets, or full tubular rivets.

Based on material, rivets can be classified as brass rivets, stainless steel rivets, steel rivets, aluminum rivets, copper rivets, etc.

What surface finishes are available for rivets?

Rivet surfaces are typically treated with rust-proofing treatments, primarily electroplating, including zinc plating, nickel plating, chrome plating, tin plating, gold plating, and silver plating. Electroplating is a common rust-proofing method for rivets. It applies a layer of plating to the rivet surface through physical or chemical methods. The plating effectively prevents corrosion and rust, while also providing a certain aesthetic effect.

Another special surface treatment method is head coating. Head coating is performed after the rivet is electroplated. This allows for a variety of colors on the rivet head, achieving an aesthetically pleasing finish.

Aluminum rivets cannot be electroplated, but they can be anodized. Anodizing also allows for a variety of color options, but the unit price is higher than electroplating.

Rust-proofing the rivet surface is crucial, effectively extending the rivet's service life and ensuring a secure connection. Different rust-proofing methods are suitable for different environments and applications, so the choice should be tailored to the specific situation.

- View as

Hule aluminiumnitter

Hulnitter i aluminium er en almindelig fastgørelsesanordning, de er meget udbredt på mange områder på grund af deres lette vægt, korrosionsbestandighed og gode elektriske ledningsevne. Nuote Metals producerer og sælger hule aluminiumnitter i Kina, vi har mere end 10 års erfaring i denne industri.

Læs mereSend forespørgselSemi hule nitter i messing

Hos Nuote Metals fokuserer vi på at lave messing semi-hulnitter. Vores nitter bruger hovedsageligt H65-messing - en kobber-zinkblanding, der tilbyder stor elektrisk og termisk ledningsevne sammen med solid korrosionsbestandighed. Dette materiale er både hårdt nok og fleksibelt nok til at fungere godt med kold heading og nitteprocesser. Plus, messing har den naturlige gyldne farve, så hvis du bruger disse til dekorative formål, behøver du ofte ikke nogen ekstra belægning.

Læs mereSend forespørgselPan Head Halv Hule Nitter

Har du nogensinde undret dig over, hvordan vores halvhule nitter er lavet? Her er en hurtig gennemgang:

Først udvælger vi den rigtige metaltråd og skærer den til den nøjagtige længde, der er nødvendig. Derefter er det afsted til den kolde styremaskine, som stanser og former tråden til den grundlæggende nitteform – det er her, grydehovedet og det hule skaft virkelig tager form. Næste op er varmebehandling; vi justerer tiden og temperaturen baseret på materialet for at sikre, at hver nitte har den rigtige styrke og sejhed. Derefter tilføjer vi ofte en beskyttende finish – tænk galvanisering eller passivering – for at hjælpe dem med at bekæmpe rust og holde længere. Og vi springer aldrig den sidste kontrol over: hver batch bliver kigget igennem for at bekræfte, at størrelsen, finishen og ydeevnen er op til standarden.

Vi er altid glade for at vise kunder rundt – hvis du nogensinde er i området, så lad os det vide, og vi arrangerer en rundvisning!

Svampehoved Halvhule Nitter

Svampehovedets halvhule nitter får deres navn fra deres tydelige kuppelformede hoved, der ligner lidt en svampehue kombineret med et delvist hult skaft. Dette design lader nitten forme sig selv under installationen, hvilket skaber et stærkt hold - perfekt til brug, hvor du både har brug for et godt udseende og solid ydeevne. Når den er indstillet, blusser den hule ende ud og griber fast, mens hovedet og den øverste del af skaftet forbliver solide for ekstra støtte.

Læs mereSend forespørgselJern halvrørsnitter

Jern halvrørsnitter er mekaniske forbindelser med en hul hale. De virker ved at klemme den hule del og flange den udad for at skabe en permanent snap-on fiksering. Kerneapplikationer er koncentreret i lette industrier såsom beklædning, fodtøj og bagage. Deres brug af blødt trådmateriale undgår revner under nittesamlinger og giver omkostningsfordele. Nuote Metals er en professionel producent af halvrørsnitter af jern. Vores nitter er af høj kvalitet, og hver enkelt gennemgår en grundig inspektion for at sikre kundetilfredshed.

Læs mereSend forespørgselHalvhule nitter med forsænket hoved

Hvorfor vælge halvhule nitter med forsænket hoved i stedet for andre tilslutningsmetoder? Dette skyldes primært deres unikke fordele. Efter installationen flugter hovedet med overfladen, hvilket undgår potentiel interferens eller sikkerhedsrisici forårsaget af fremspring. Det semi-hule design gør nitteprocessen relativt enkel og kræver intet komplekst udstyr; det kan normalt udføres manuelt eller med pneumatisk værktøj. Denne type nitte er velegnet til materialer af varierende tykkelse og kan tilpasses forskellige situationer ved at justere nittekraften.

Læs mereSend forespørgselWhat are the advantages of rivets over other fasteners?

1. Ease of Installation

Rivets are fast to install, and even fully automated for high-volume applications, resulting in a simple and efficient operation process.

2. Connection Reliability

The riveting process is standardized, with strict quality control, resulting in highly stable connections. Visual inspection allows for quick verification of connection quality.

3. Vibration and Impact Resistance

Rivets connect through deformation or interference fit, providing strong clamping force and excellent vibration resistance, capable of withstanding vibration and shock.

4. Low Cost

Rivets are easy to install and can be fully automated, saving significant labor costs.

What are the advantages and disadvantages of rivets made of different materials?

Aluminum Rivets

Advantages: Lightweight, reduces overall product weight, low cost, suitable for general civilian applications.

Disadvantages: Low tensile and shear strength, unsuitable for high-strength workpieces, prone to electrochemical corrosion when in contact with metals such as stainless steel.

Stainless Steel Rivets

Advantages: Strong corrosion resistance, high hardness, suitable for high-strength workpieces (such as marine equipment)

Disadvantages: Higher cost, typically more expensive than aluminum rivets of the same specification.

Brass and Copper Rivets

Advantages: Excellent conductivity (such as connecting electronic components), good corrosion resistance.

Disadvantages: Higher cost, more difficult to process.

Steel Rivets

Advantages: High hardness, high connection reliability, and wide applicability.

Disadvantages: Compared to other materials, iron rivets are more prone to rusting.

What are the main applications of rivets?

Rivets have a wide range of uses, from small items like a pair of scissors to large items like airplanes and ships, as well as in high-precision medical applications.

Industrial Manufacturing

Rivets are used in a wide variety of industrial fields, wherever there is a need to connect two or more materials.

Electronics

Rivets secure heat sinks and chips, providing both vibration damping and noise reduction, and are widely used in the cooling systems of electronic products such as computers and mobile phones.

Automotive

Rivets are widely used to connect components of automobile bodies and chassis, such as doors and hoods. Their lightweight and corrosion-resistant properties make them an indispensable joining method in automotive manufacturing.

Aerospace

In aircraft manufacturing, rivets are used to connect different fuselage components, such as wings and tailplanes. Millions of rivets create high-strength, corrosion-resistant joints. Aluminum and titanium alloy rivets are often used to connect components of corresponding materials, ensuring stability in extreme environments.

Rivets are used everywhere. The above examples only represent a small number of their applications. We see rivets everywhere in our daily lives, such as on scissors, folding beds, and strollers etc. Rivets can be customized to different sizes and materials depending on the application.

Nuote Metals has specialized in the rivet industry for over a decade. Our factory is located in Dongguan, a city known as the "World Factory," a city with a developed industry and convenient transportation. This allows us to respond quickly when acquiring raw materials and supporting surface treatments, meeting our customers' needs for quick access to samples and bulk orders. We produce 10 million rivets daily and have molds of various specifications, allowing us to produce rivets as small as 0.8mm and as large as 10mm. We welcome your inquiries and visits.