Nitter

As one of professional manufacturer in China, Notin would like to provide you Rivets. And we will offer you the best after-sale service and timely delivery.

What is a rivet?

A rivet is a permanent mechanical fastener used to join two or more materials. Rivets work by inserting a metal pin into an aligned hole and deforming the end, creating a strong, secure, and durable connection. Unlike temporary fasteners like screws, rivets do not rely on threads, but instead form a permanent connection, making them ideal for applications requiring high strength, durability, and vibration resistance.

Classification of Rivets

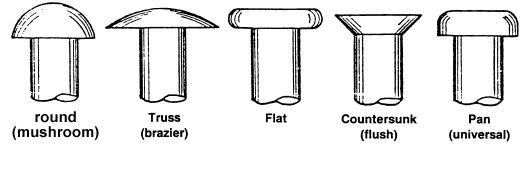

Rivets are typically categorized by head shape, degree of hollowness, or material.

Based on head shape, rivets can be classified as flat head rivets, round head rivets, countersunk head rivets, mushroom head rivets, universal head rivets, truss head rivets, etc.

Based on degree of hollowness, rivets can be classified as solid rivets, semi-tubular rivets, or full tubular rivets.

Based on material, rivets can be classified as brass rivets, stainless steel rivets, steel rivets, aluminum rivets, copper rivets, etc.

What surface finishes are available for rivets?

Rivet surfaces are typically treated with rust-proofing treatments, primarily electroplating, including zinc plating, nickel plating, chrome plating, tin plating, gold plating, and silver plating. Electroplating is a common rust-proofing method for rivets. It applies a layer of plating to the rivet surface through physical or chemical methods. The plating effectively prevents corrosion and rust, while also providing a certain aesthetic effect.

Another special surface treatment method is head coating. Head coating is performed after the rivet is electroplated. This allows for a variety of colors on the rivet head, achieving an aesthetically pleasing finish.

Aluminum rivets cannot be electroplated, but they can be anodized. Anodizing also allows for a variety of color options, but the unit price is higher than electroplating.

Rust-proofing the rivet surface is crucial, effectively extending the rivet's service life and ensuring a secure connection. Different rust-proofing methods are suitable for different environments and applications, so the choice should be tailored to the specific situation.

- View as

Stålrør nitter

Stålrør nitter giver fordele såsom lethed, høj styrke, korrosionsbestandighed, fremragende lufttæthed og høj pålidelighed. De er velegnede til at deltage i en række forskellige materialer, såsom aluminiumslegeringer, stål og plast. Endvidere reducerer den hule krop af stålrør nitter markant deres vægt og bidrager til den samlede letvægt af strukturen.

Læs mereSend forespørgselRør river i rustfrit stål

River i rivfrit stål består af en krop og en hætte med en hul kanal derimellem. Dette design giver Rivet mulighed for at sikre materialer ved at presse eller udvide under sammenføjningsprocessen. Rustfrit stål blev primært valgt til dens korrosionsbestandighed. Krom i rustfrit stål danner en oxidfilm på overfladen, hvilket forhindrer rust og forlænger livets liv. Rustfrit stål tilbyder også fremragende sejhed og styrke, hvilket gør det velegnet til en lang række miljøforhold. Nuote Metals er en rørfaglige rivet -producent i Kina i mere end 10 år.

Læs mereSend forespørgselRør nitter

Rør nitter bruges typisk i applikationer, hvor fastgørelse er påkrævet, men ekstrem styrke er ikke. I elektroniske enheder kan de for eksempel bruges til at forbinde kredsløbskort eller boligkomponenter. I møbelproduktion kan de bruges til at fastgøre metal- eller træstrukturer. Nogle dekorative genstande eller små mekaniske enheder bruger også disse nitter.

Læs mereSend forespørgselEyelet nitter

Eyelet -nitter er en alsidig nitte, der ofte bruges til at forbinde tynde aluminium og stålplader. De er kendetegnet ved smukke nitende punkter, stærk struktur og justerbar højde. De er egnede til at tilslutte forskellige metalplader og forskellige materialer. Eyelet-nitter kan poleres hot-dip til at danne et beskyttende lag på overfladen, som har antistatiske, korrosionsbestandige og anti-allergiske egenskaber.

Læs mereSend forespørgselMessingrør nitter

Messingrør nitter er et almindeligt mekanisk fastgørelseselement, der bruges på tværs af en lang række industrier. De er hule cylindriske og har typisk brims i hver ende. Messingrør nitter opnår en forbindelse gennem deformation og tilbyder fremragende elektrisk ledningsevne, korrosionsbestandighed og let installation.

Læs mereSend forespørgselMalede farverige nitter

Malede farverige nitter er nitter med hovedmalet, de kunne males med forskellige farver, såsom rød, grøn, sort eller hvad du vil. Nuote Metals tilbyder malede nitter i forskellige størrelser, velkommen til at sende os din forespørgsel.

Læs mereSend forespørgselWhat are the advantages of rivets over other fasteners?

1. Ease of Installation

Rivets are fast to install, and even fully automated for high-volume applications, resulting in a simple and efficient operation process.

2. Connection Reliability

The riveting process is standardized, with strict quality control, resulting in highly stable connections. Visual inspection allows for quick verification of connection quality.

3. Vibration and Impact Resistance

Rivets connect through deformation or interference fit, providing strong clamping force and excellent vibration resistance, capable of withstanding vibration and shock.

4. Low Cost

Rivets are easy to install and can be fully automated, saving significant labor costs.

What are the advantages and disadvantages of rivets made of different materials?

Aluminum Rivets

Advantages: Lightweight, reduces overall product weight, low cost, suitable for general civilian applications.

Disadvantages: Low tensile and shear strength, unsuitable for high-strength workpieces, prone to electrochemical corrosion when in contact with metals such as stainless steel.

Stainless Steel Rivets

Advantages: Strong corrosion resistance, high hardness, suitable for high-strength workpieces (such as marine equipment)

Disadvantages: Higher cost, typically more expensive than aluminum rivets of the same specification.

Brass and Copper Rivets

Advantages: Excellent conductivity (such as connecting electronic components), good corrosion resistance.

Disadvantages: Higher cost, more difficult to process.

Steel Rivets

Advantages: High hardness, high connection reliability, and wide applicability.

Disadvantages: Compared to other materials, iron rivets are more prone to rusting.

What are the main applications of rivets?

Rivets have a wide range of uses, from small items like a pair of scissors to large items like airplanes and ships, as well as in high-precision medical applications.

Industrial Manufacturing

Rivets are used in a wide variety of industrial fields, wherever there is a need to connect two or more materials.

Electronics

Rivets secure heat sinks and chips, providing both vibration damping and noise reduction, and are widely used in the cooling systems of electronic products such as computers and mobile phones.

Automotive

Rivets are widely used to connect components of automobile bodies and chassis, such as doors and hoods. Their lightweight and corrosion-resistant properties make them an indispensable joining method in automotive manufacturing.

Aerospace

In aircraft manufacturing, rivets are used to connect different fuselage components, such as wings and tailplanes. Millions of rivets create high-strength, corrosion-resistant joints. Aluminum and titanium alloy rivets are often used to connect components of corresponding materials, ensuring stability in extreme environments.

Rivets are used everywhere. The above examples only represent a small number of their applications. We see rivets everywhere in our daily lives, such as on scissors, folding beds, and strollers etc. Rivets can be customized to different sizes and materials depending on the application.

Nuote Metals has specialized in the rivet industry for over a decade. Our factory is located in Dongguan, a city known as the "World Factory," a city with a developed industry and convenient transportation. This allows us to respond quickly when acquiring raw materials and supporting surface treatments, meeting our customers' needs for quick access to samples and bulk orders. We produce 10 million rivets daily and have molds of various specifications, allowing us to produce rivets as small as 0.8mm and as large as 10mm. We welcome your inquiries and visits.